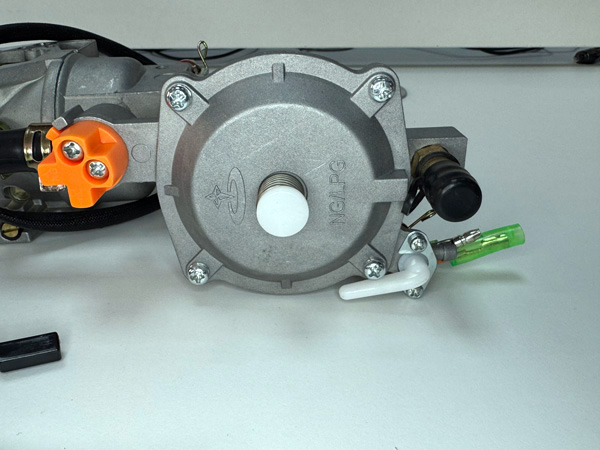

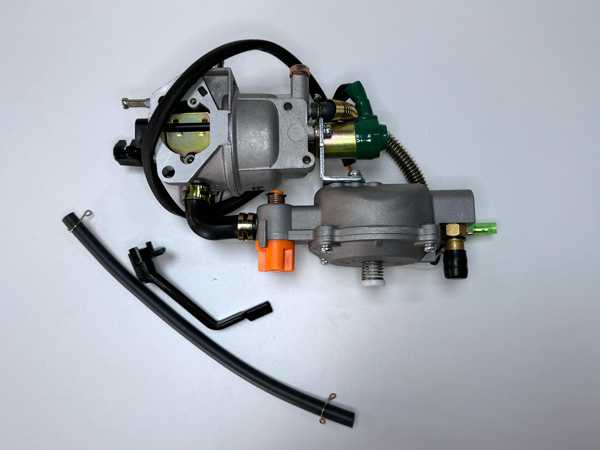

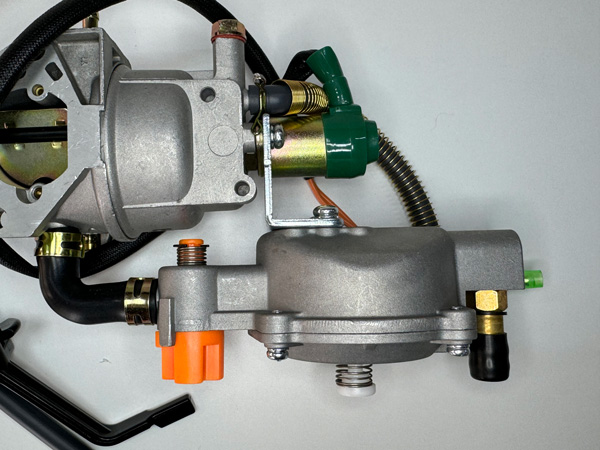

1. Oil-to-gas conversion points:

- When running the engine on a gaseous fuel, such as natural gas or liquefied petroleum gas (LPG), the oil-to-gas conversion can be performed directly while the engine is operating.

- Switching from petrol to gas requires waiting until the petrol is almost burned out before gradually opening the gas valve to switch fuels. Since the carburetor of a petrol engine may have a certain amount of residual petrol, it may take about 2 minutes of starting and running before the engine operates properly.

- On the flip side, switching from gas back to petrol requires opening the petrol tank switch and gradually closing the gas valve to make the switch.

2. Switch off the gas supply properly:

- When the engine is switched off, it is recommended to close the gas supply valve to ensure safety and prevent accidental leakage.

- If the engine will not be used for a longer period of time, it is also recommended to switch off the gas supply to maintain the equipment.

3. Starting problems:

- When starting an engine that uses gas as fuel, it is necessary to check that the pressure reducing valve connected to the throttle tank is a low pressure valve suitable for domestic use. If not, it should be replaced with a suitable domestic pressure reducing valve. Also, the length of the gas pipe should not exceed 3.5 metres.

- If the machine has a discharge from the exhaust or is difficult to start when using gas fuel, it may be necessary to replace the spark plug with a higher quality one.

- If the engine is still difficult to start or runs abnormally after replacing the spark plugs, you need to check if the high pressure pack (ignition module) is working properly and if the oil is sufficient.

NOTE: The above steps should be performed by a professional to ensure safety and that the manufacturer's operating manual and safety instructions are fully understood before converting the oil and gas system or operating the engine. Improper operation may result in a safety risk.

50000㎡

50000㎡

200

200 100sets

100sets

6million

6million

400

400

+86 13905935263

+86 13905935263